At Lawler Gear, our team has the reverse engineering experience to help you develop a 3D CAD and manufacture most types of gears. We use software and techniques to analyze your existing parts and create a detailed, accurate 3D model with SolidWorks.

Our reverse engineering services help you reduce costs, improve efficiency, and increase productivity. We understand that time is of the essence, which is why we work quickly and efficiently to deliver your project on time and within budget.

Our reverse engineering services help you reduce costs, improve efficiency, and increase productivity. We understand that time is of the essence, which is why we work quickly and efficiently to deliver your project on time and within budget.

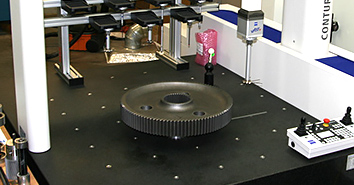

Our skilled machinists use advanced equipment to capture precise measurements of your existing parts, and our software can create a 3D model that can be used to manufacture new parts or systems.

Lawler Gear has several resources to work with: our in-house computer programs and our analytical gear inspection equipment. We’ll use these tools to ensure your gear is exactly the same as your sample, damaged or worn gear that was provided.